Please read the Disclaimer before

attempting any work in this FAQ.

Updated 22 feb 2003 by Spakur

Missing Sprocket Carrier Circlip

by Kristian #562

Q. My Sprocket Carrier seems to have moved

away from the Hub and is very close to the RHS Swing Arm. What could be

the Problem.?

A. Either the Factory or the last person to do the Wheel Bearings in the

Sprocket Carrier forgot your Circlip.!

This is a letter I wrote to BMW about a missing Circlip.

Dear Sir,

I am the owner of a Blue 2000 BMW F650GS. Two weeks ago I noticed that my bikes’ Sprocket Carrier seem inordinately loose and the Rear Sprocket was very close to the Right Hand (RH) Swingarm. The mileage on my bike is currently 5000km’s.

I am very familiar with the BMW F650, having worked extensively on my previous 1996 BMW F650 over a period of several years. As I am mechanically minded and the bike is out of warranty in any case, I took the wheel off to see what the problem was.

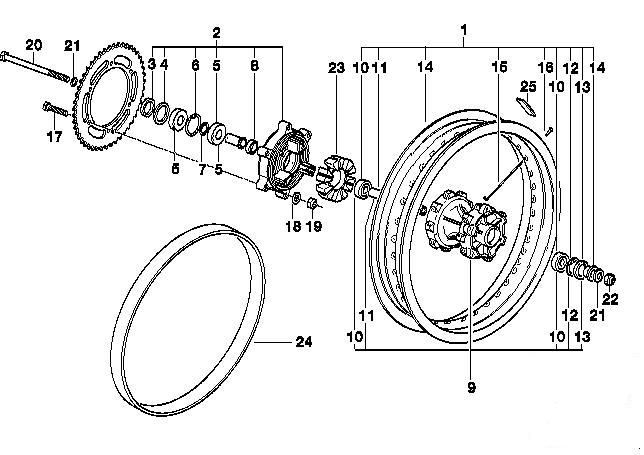

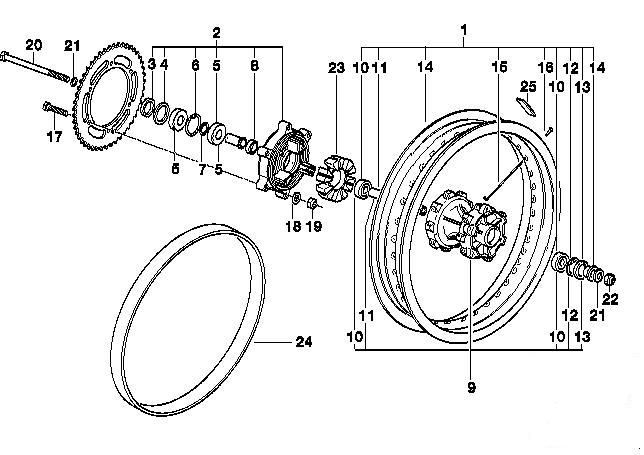

Referring to the attached Diagram 1, sure enough, the Sprocket Carrier Hub (Part 2) had been rubbing against the Swingarm. Fortunately there is not too much damage to the inside face of the Swingarm, it is not too deeply grooved, but the Hub has worn all the paint off the inside of the Swingarm.

In addition, and much to my chagrin, the Swingarm had worn down the outer rim of the Softer Aluminium Sprocket Carrier Hub, with the result that there were deep gouges on the end face of the Hub. Due to the rubbing of the Sprocket Carrier Hub against the Swingarm, an aluminium lip had also formed over the outer edge of the Seal (Part 4), basically enclosing the seal, making it impossible to remove as it was. The Outside Spacer (Part 3) was still there, but appeared to be a bit more recessed in the Seal (Part 4) than it should have been, with it being pretty much flush with the end face of the Hub, not proud of it, as it should be.

My first thoughts were of missing parts, however looking at the outside of the Sprocket Carrier it was clear none of the Spacers were missing. The Spacer on the LHS of the Wheel (Part 14), i.e. the Brake Disk side, was also in place, albeit with a Groove worn part way around the circumference, presumably as a result of the Sprocket Carrier Movement on the other side. The Cush Drive Rubbers (Part 23) also had grooves in the side, presumably from the Sprocket Carrier moving out of the Wheel Hub and bearing on the outer part of the rubber.

Closer inspection INSIDE the Sprocket carrier showed that the Inside Bearing (Part 5) had moved out of its seat in the Sprocket Carrier by a few mm, in the direction of the Left Hand (LH) Swingarm. Referring to the attached Diagram 2, coupled with the inside Spacer, which sits up against the Wheel Bearing in the WHEEL HUB (Part 10), the result was that the whole Sprocket Carrier had moved to the Right, away from the Wheel Hub, toward the swing-arm. In doing so, the Outside Spacer (Part 3), had moved INTO the Carrier by the same amount that the Bearings and Inside Spacer had moved OUT of the Carrier.

It thus appears the Outside Bearing (Also Shown as Part 5) (of the two in the Sprocket Carrier) i.e. the one closest the swingarm should have been held in place in the Sprocket Carrier by the Circlip (Part 6) that sits between the two bearings. Holding the Bearing in place stops the Outside Spacer (Part 3) moving inward. With nothing restraining it, the Bearings can move RELATIVE to the Sprocket Carrier and there is only one way it can go, i.e. toward the RH Swingarm.

I decided to replace the Sprocket Carrier Bearings (2 # SKF 6204-2RS/C1) and Seal as I needed to open up the Sprocket Carrier to check whether the Circlip was indeed Missing or Broken. Sure enough, on removal of the Inner Bearing (Part 5), it was clear there never was any Circlip in that Sprocket Carrier. I can only imagine it had been left out at the Factory as a Motorbike with that very low mileage on it certainly should never have any need for anyone to do any work on the Sprocket Carrier Bearings. I had to both file and sand down the Sprocket Carrier Hub to remove the Outer Seal (Part 4).

I also replaced the Brake Side Wheel Bearing (SKF 6203-2RS), which was stiff and slightly “crunchy” probably as a result of the Movement of the Sprocket Carrier.

If you wish to view the Rubbed Swingarm and the Filed/Sanded down Sprocket Carrier Hub I am perfectly happy to bring the bike to you for inspection. I may also have the old Bearings and Seals I removed from the Bike.

I trust I need not tell you the consequences of the Sprocket Carrier Retaining Bolts getting sheared off by the Swingarm, nor the subsequent throwing off of the Chain and locking up of the Wheel, at Hong Kong’s maximum Speed Limit of 110km/h.

So why am I writing to you about all this.? I am extremely angry that any Company, but particularly BMW, to whom one pays a premium for supposed quality and Superior Engineering, should allow an Employee to assemble a bike in such a manner that puts me and my Fiancé at the risk of at least grave injury if not a Fatal injury. You will be aware that you fixed the Water Pump on this bike after 2300 km’s. The failures and omissions on this bike thus far do not fill me with the confidence BMW would have you believe.

The Serial number of my bike is WB10172A1YZE34317. I would be grateful if you would transmit this correspondence to BMW in Germany. If there is some sort of checking system in BMW’s factory they should be able to determine who was responsible for assembling that part of my bike, as the employee who forgot this part needs to be told about it.

Sprocket Carrier Rubber Dampers

Q: There seems to be some play between the sprocket carrier and the axel. The movement isn't towards the swing-arm, but is rotational. If I hold the wheel still I can still turn the sprocket a bit. I've never noticed this before while doing routine chain mantainence and the bike hasn't been exhibiting any odd handling characteristics. Tell me please that this is perfectly normal and I can go back to cursing this stupid November snow fall, or better yet just take a nice nap in front of the fire and ignore the world. (Sean)

A: The sprocket is not directly fixed to the wheel. It is directly fixed by the six bolts that you can see to a basket-like case that Clymer calls a driven flange (you can see it if you look from the other side or from behind). This driven flange is divided into compartments that mesh with matching compartments on the hub. The compartments are filled with a rubber damper. It seems to me that your rubber damper has aged. It's very easy to get in there to inspect, see the FAQ that describes real wheel removal. (Alexander in Dubai)

A: There's nothing to strip down, really. Remove the rear wheel, and the sprocket carrier lifts right off the wheel, no bolts to remove. You'll be able to see the circular rubber damper. Should be a cheap fix. There really isn't any other way that the sprocket carrier could move rotationally without moving the wheel. (mark #403)

A: If the carrier bearing is shot, the carrier could rotate slightly with respect to the wheel. But it would also have lateral slop if that was the case. I put my money on a fragged cush rubber. (Flash)

A: My bike is the same age as yours and at 12,000 miles (Summer 2002) my BMW dealer gave me a set FOC as there has been a recall on early damper rubbers (though my bike was not on the recall list). Mine were not worn but had broken up into a sticky gooey mess which I found when I removed the wheel to get a puncture fixed. Its worth a try at your local dealer...remind them of the recall. (Chris)