F650 technical tips

Disclaimer

These technical tips are for guidance only. No one accepts any

responsibility for their accuracy. Before working on your machine satisfy

yourself that you know what you are doing.

If in doubt, don't do it.

If it ain't broke, don't fix it.

Information Sources

Some of the information here is from e-mail correspondents, one of whom has

told me of a manual.

Revue Moto Technique no 96

Written by: E.T.A.I. 96 rue de Paris - 92100 Boulogne Billancourt.

Sales:

Librairie Trame - 62 bd Jean-Jaoures - 92100 Boulogne Billancourt, France

Tel: (1) 46 03 48 69

Cost: 118Fr plus 20Fr P&P

This booklet summarises both routine and major tasks in French.

Until an English workshop guide is available this is fine.

Comments

My bike is used during the winter, left out of doors and

otherwise abused. This means that I clean all the bits of bodywork, screws,

clamps and others bits and pieces as I go along. It takes longer but the bike

weighs less afterwards!

There are two benefits of DIY work. First you can save some labour costs and

second you know where bits come from; a bonus if you breakdown miles from a

friendly dealer. It's not worth using dodgy parts, they take

just as long to fit, you don't save much money really and they may kill you. Use

the saving in labour costs to keep the oil fresh and things smooth and smart.

Take the bike into the dealer for any job that you regard as

tricky.

I'll assume that you've all got the normal F650 tool roll, a centre stand and

the short rider and technical guides supplied with the machine.

Oil and filter change

It's always smart to have clean

oil in a stressed thumper.

Tools

In addition to the standard toolkit this job is easier with 10mm,

17mm and deep 17mm sockets. You'll also need a 2 litre tray and a jar that holds

around a litre or a piece of inch pipe.

Parts

Paper oil filter, washer kit comprising large and small O-ring,

and 2 aluminium washers. Just over 2 litres of quality four stroke oil of grade

SAE 5W50.

The task

- Warm up the engine, maybe go and buy the oil.

- Remove plastic sump guard - this will save mess later on.

- Clean around sump plug on base of engine and reservoir plug on front of

frame within the loop of left hand exhaust.

- Remove sump plug, open filler cap and allow oil to drain into tray. Try to

keep used oil off your skin.

It's carcinogenic and may be hot.

It's carcinogenic and may be hot.

- Remove reservoir plug, expect the oil to squirt forwards onto the front

tyre. Catch it with your jar or pipe. You'll get around a litre from each

source.

- Leave to drip and turn attention to filter.

- Remove cover over primary sprocket. You'll have to hold the brake pedal

down to do this. Remove all of that nasty dirt and chain oil.

- Clean around filter cover and move tray.

- Remove cover and collect another dribble of oil. Pull filter out of

housing by hand, trying not to make a mess.

- You should also clean a mesh filter in the oil reservoir

- Remove petrol tank

as detailed

- Identify an oil line leaving frame on left of frame behind radiator

- Undo oil pipe (You do have a replacement clip don't you?)

- Use a deep 17mm socket to remove the filter assembly

- Clean the mesh with air or petrol and replace O-ring

- Refit filter and tighten to firm hand tight

- Clean around all openings and refit plugs with fresh washers.

- Tighten plugs to firm hand tight.

Take care to replace sump

plug without damaging threads.

Take care to replace sump

plug without damaging threads.

- Pour a little oil into filter and refit in cavity, refit cover with fresh

O-ring.

- Torque settings

| Sump plug |

RMT manual lists 40Nm, a Pegaso rider suggested 20Nm

now I adopt

firm enough to compress crush washer |

| Reservoir plug |

10Nm |

| Filter cover screws |

10Nm |

NB I find that the specified torque for the reservoir plug

is inadequate even with a fresh alloy washer and so I usually do it until it

is tight using a short spanner. By contrast, the sump plug is easy to

overtighten causing damage to sump thread. Don't think it won't happen to you

as BMW list a repair kit based around a Helicoil insert. If damage is minor

you'll find that a K-series plug and crush washer are a lot longer and will

utilise sound thread in the sump (Thanks Lee for the tip).

- Pour in around 1.8 litres of oil, leave to stand.

- Run starter for 10 seconds. Wait some more (do plugs perhaps). Re run

starter and allow to start. This is real scary watching oil pressure light

stay on a few seconds!

- Check oil level as manual and top-up as required.

- Refit sump guard.

- Check front and rear tyres for oil spills- clean if

needed.

I don't know how important this is. After 3k to

6k miles of use mine look fine.

Tools

Standard kit.

Parts

2 plugs, gapped at 0.6mm to 0.7mm. WD-40 and tissue or clean rag.

The task

- Remove right hand side grey engine cover.

- Gently pull off HT leads, noting which is which (don't know if this is

important).

- Clean leads and cylinder head with tissue/WD-40. You don't want any of the

dirt road in the cylinder.

- Remove plugs using your fingers once they're loose enough. Examine for

crack, over heating, oil fouling or whatever you may recognise!

- Fit plugs by hand to avoid cross threading. Then tighten

to 20Nm, or a quarter turn after hand tight.

- Refit HT leads and engine guard.

Time and cost

Plugs and oil change takes around 2 hours depending how

much cleaning you do! A service kit (comprising filter, plugs and washers) costs

around £12, depending on source.

Air filter

If you live by the beach this must be very

important. Mine is nice and clean most of the time - but once the Airbox had

water running around and the engine ran terribly. I don't know how it got in!

Tools

An 8mm nut spinner saves fiddling, but standard toolkit adequate.

Parts

A little petrol and filter oil, some newspaper

and lots of clean rags.

The task

- Remove left hand cover and battery. Lots of places to get salt out of.

Clean around relay area in particular.

- Remove two bolts at top and bottom of starter relay carrier and lift out a

cover about 4cm by 15cm.

- Slide out filter cassette. Separate into foam and two pieces of plastic.

Wash filter in petrol and allow it to dry. Run a little filter oil into a

plastic bag add the filter and work the oil in, add more oil and repeat.

Squeeze to remove excess and allow the solvent to evaporate. Recently BMW have

specifically advised against using engine oil for this.

- Find the Airbox drain pipe hanging inside the left foot peg support. It is

capped with a bung retained by a spring clip. Get a little jar under it and

then remove the bung and let the greasy water out. This seems to need doing

between services if you drive through a lot of spray. Old Fs have air holes in

the top of the Airbox. Last time mine was in the dealer they covered these

with gaffer tape. I suppose it reduces airflow but I guess this might be to

reduce water ingress. The drain pipe loops underneath the battery box, make

sure there's nothing trapped in a U-bend. Replace bung and clip.

- Clean around the inside of the Airbox with a rag. Don't

shove it into the carb. inlets. Some people suggest a light smear of grease in

the Airbox helps to catch particles that have penetrated the filter.

- Clean and check battery level while it's out.

- Reassemble the filter and grease its edges. Reassemble everything.

Time and cost

The length of time taken depends on how stripped down the

bike is before you begin. The job itself takes less than 20 minutes. Negligible

cost.

If you drag the rear brake on roundabouts these may last no more than 8k

miles, otherwise twice that is reasonable.

I must stress that you should know

how to do this job, and be reading this merely to confirm what you already know.

If you get it

wrong it will be dangerous.

If you get it

wrong it will be dangerous.

Tools

Standard toolkit plus a small hammer, old screwdriver about 3mm to

4mm diameter, tooth brush, 10ml disposable plastic syringe.

Parts

Brake part cleaning spray, pair of pads, copper grease, cotton

swabs on sticks.

The task

- Clean calliper with spray and tooth brush. Remove right hand body cover and

wipe around reservoir.

- Examine the calliper and see if the pad retaining pin can be rotated by

hand with the split pin. If it can, OK, if not you'll have to decide how much

force to use later on.

- Remove and retain split pin.

- Gently tap out pin from left hand side using old screwdriver as a drift.

Once the pin has moved around 4mm it will be loose as it has a spring collar

on it. Remove and clean pin.

- Lift out pads and examine them and disc for scratching. You've not left it

too late have you?

- Clean internal surface of calliper and piston with brake cleaner spray and

cotton swabs.

- Loosen lid of fluid reservoir.

- Lever calliper from right hand side (i.e. adjacent to wheel) to width of new

pad. While doing this check for, and maybe remove with syringe, excess brake

fluid in reservoir.

- Fit wheel-side pad, ensuring that locating lug is in place.

- Lever piston into calliper, again remove excess fluid as it runs back to

reservoir.

- Fit pad, again checking locating lug.

- Realign pads, double check that they are located properly

and replace retaining pin, having put the smallest possible

amount of copper grease onto the spring collar.

- Tap the pin home and refit split pin.

- Press pedal a few times to centre calliper and top up fluid level with

fresh fluid. Replace cover.

- Check for binding and stopping ability before riding off.

Time and cost

This job takes around 40 minutes. Genuine BMW pads cost

around £28 and Brembo £15. Unlike other bits of the bike there doesn't appear to

be any BMW marking on the pads (last time I looked anyhow) and the code number

on the BMW pads showed that they are the same Brembo ones. It's your choice, but

hard compound will destroy expensive discs, I expect Brembo will be OK. Can

anyone report on extended use of non-Brembo pads?

Front brake pads

This job is almost identical to the above, except:

- Remove plastic calliper guard.

- Remove calliper off fork

- As you remove the pads check the arrangement of a flat spring steel

retaining clip and ensure that it is correctly orientated on reassembly.

- Replace calliper and tighten bolts very firmly

Valve clearances

It is important to check the clearance between the valve shims and the cam

shafts to ensure that the gap has not worn away. This will cause

serious damage to the cylinder head and or the piston.

Before

beginning the job you must consider if you are likely to need to replace the

shims (i.e. adjust the clearance). This is a harder job, not yet described here,

that needs specialist parts and tools. Rumour has it that once the engine has

bedded in and the shims replaced at say 6000 miles then an averagely ridden

machine will not require replacement for many miles. Two of mine were reshimmed

(don't know which) by the dealer at 6000 miles. At 32000 miles they are still in

tolerance (a dealer checked it at 23000 miles).

Before

beginning the job you must consider if you are likely to need to replace the

shims (i.e. adjust the clearance). This is a harder job, not yet described here,

that needs specialist parts and tools. Rumour has it that once the engine has

bedded in and the shims replaced at say 6000 miles then an averagely ridden

machine will not require replacement for many miles. Two of mine were reshimmed

(don't know which) by the dealer at 6000 miles. At 32000 miles they are still in

tolerance (a dealer checked it at 23000 miles).

Tools

A low range torque wrench is thought by some to be advisable. A

10mm socket to fit above and a set of feeler gauges are essential. You also need

a large straight screwdriver and a 6mm long Allen key and T-bar.

Parts

A replacement 10mm screw clip for the oil breather hose unless you

have the special tool to allow you to refit the OEM clip. Clean newspaper.

The task

- The engine must be cold to check the valve clearances. It's also helpful

if the petrol tank is nearly empty.

- Remove grey plastic pieces either side of engine.

- Disconnect the petrol feed pipe at the tank tap (plug or cover this to

stop dirt going into the system) and the tank breather pipe at a joint hidden

under the rear left corner of the tank, accessible from the seat area.

- Remove the petrol tank by undoing the body work Allen screws and the rear

bolt under the seat. Slide the tank backwards and then lift. So you know, it

has 4 tabs that hold locate it into the front fairing and underneath, two

grooves that slide onto rubber bosses on the frame spine.

- Clean the exposed frame and cylinder head cover taking care not to get the

spark coils too wet. Leave to dry. It'll be messier here than you'd expect!

- Detach oil breather hose from frame reservoir.

- Detach the spark plug leads and remove a spark plug.

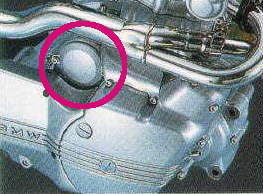

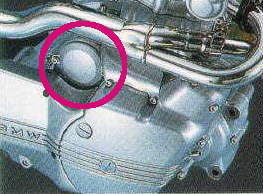

- Remove the 'button' from the centre of the alternator housing on the

right-hand of the crankshaft and fit the 6mm Allen key. This is to turn the

engine.

- Loosen and remove the 10mm bolts around the periphery and in the middle of

the head cover and remove it to the left hand side. It's a bit fiddly to get

it off above the timing gear and below the frame but it will

fit. Watch out for the bolts catching on the cams.

- Turn the engine clockwise to TDC on compression. Check the compression

using a finger over the spark plug hole. The lobes of the cams should be

pointing 'outwards' and the lines scored on the left side of on the timing

gears dead horizontal and inline with each other.

- Check the clearances by sliding a gauge between the cam lobe and the upper

surface of the valve shims. The right hand gaps are obvious, left can be

accessed via slits in the cam shaft bearing carrier. The clearance should be

between 0.10mm and 0.15mm. Write down the gap for future reference.

- If they are OK then reassemble. If not, you have to change the shims. I

suggest you reassemble and take the bike to a dealer who will have the set of

shims.

- Replace alternator 'button' very gently. The metal is

soft.

-

Replace cylinder head cover and gently replace bolts, working around the

cover. Torque to 10Nm either using torque wrench or by feel using a small ring

key.

NB I'm told that it is a bad idea to use a wrench on 'old'

bolts as they will shear at the specified torque due to fatigue and oil on the

thread. You have been warned.

- Replace oil breather hose (using your new clip) and spark plug and leads.

- Replace petrol tank and reconnect petrol feed and the breather.

The tank can be fiddly to get back into final position. Get it right and check

that the pipes aren't kinked.

Time and cost

It takes a while to remove and replace the tank, but this

speeds up plug changing. Removal and replacement of the head cover takes under

half an hour. It's only a few minutes work to check the clearances. Negligible

cost.

Introduction

The rear BMW/Showa monoshock on my F650 lost damping and some

support at around 20,000 miles. This appeared as a huge drop as the machine came

off the centrestand accompanied by a clunking noise. When the rear was lifted up

and down with the grab rail the machine felt heavy and dead. I'd

noticed this whilst I was in Spain but it took someone to point it out to me for

me to really believe there was a problem!

The BMW replacement is £400 - I was not able to find a company that

will rebuild them.

Serious riders such as Helge P. recommend using an Ohlins shock. I'm beginning

to see why.

I was told by an Aprilia dealer that the Pegaso shock fits but I was

not convinced. I chose a rebuildable Hagon, made in the UK for £200,

with a full 2 year guarantee. When fitted, the bike sagged rather too much and

after 2,000 miles it was flat on the floor. After asking Hagon for advice they

advised increasing the preload by a maximum of 10mm although they were surprised

that I was dissatisfied. The shock needs to be removed to do this as it has

traditional collars and these cannot be rotated in situ. After a few

thousand more miles I decided that the sag was still excessive as the bike would

readily bottom out with any load above me on it.

Another call to Hagon and they agreed to supply a 180kg/cm spring rather than

the original 150kg/cm. This was also a bit longer than the original and so about

5mm preload had to be used to get the collars properly screwed on. This is now a

great improvement, giving no sag on an unladen bike and only a bit with myself

and luggage. Clearly this would be an unsuitable setup on a lightly loaded

F650.

Parts

A new shock, rags or tissues, petrol, MDS-based longlife chassis

grease

Tools

Centrestand, house brick, standard toolkit, 17mm and 19mm sockets,

10mm WAF Allen key or wrench fitting, medium range torque wrench, long nose

pliers or thin fingers.

The task

- Support bike on centrestand, reduce preload to minimum and remove plastic

side panels.

- Identify suspension linkages and clean bolt heads with a petrol-dampened

rag so that they can be removed without damage.

- Loosen bolts

- upper monoshock - 8mm WAF Allen and 17mm socket

- lower monoshock - 17mm socket

- linkage bolt - 10mm WAF Allen and 19mm socket

so that they can

be removed readily when needed.

- Support rear wheel on brick so that the weight is taken. Considering tread

depth etc this equates to lifting wheel about 10mm.

- Remove linkage bolt ensuring that you retain a large washer from each

side. This can be withdrawn with fingers alone if the wheel is supported

correctly.

- Lift wheel and swing arm at least 25cm by supporting the wheel on the end

of the brick. This should completely expose the lower monoshock bolt.

- Remove the monoshock bolt (17mm socket) retaining both a plain and a

spring washer. There is not a nut as the shock bracket is threaded.

- Push the two linkages that are hanging from the swing arm so that they

face backwards and tape up if need be. Remove remote preload reservoir from

the frame by undoing the 10mm WAF bolt.

- Remove upper monoshock retaining bolt (you may need pliers to extract the

bolt between the various black breather pipes) holding the shock with your

other hand. Retain a washer from each side. Mine had only one washer. I

suspect that this was because the welding had run onto the attachment point

and a washer would not have fitted flat.

- Carefully withdraw the shock down through the swingarm, making sure that

the preload system doesn't get stuck.

- Clean all exposed suspension linkages surfaces and bolts/washers. The

bearings contain needle rollers so don't wash too much petrol around or get

grit inside them. Regrease bearings.

- Reassemble in the opposite order making sure that the threaded side of the

lower shock bracket faces the right hand side and the damping screw is

accessible from the left. It is advisable to put Loctite on threads.

- If you are using a Hagon shock it is worth checking the preload

setting before tightening everything up. The adjustment rings are

not accessible when assembled.

- Tighten the bolts to:

- Upper monoshock 50Nm

- Lower monoshock 30Nm

- Suspension linkage 80Nm

- Remote reservoir retaining bolt 2.5Nm

- Re-examine everything and after making sure that the brick is out of the

way take the bike off the centrestand. It should feel better. Mine did! Adjust

preload and damping as required.

Time and cost

Around 3 hours. Cost depends on your choice of shock but

it's going to be between £70 for a rebuild and £600 for an Ohlins.

Introduction

The fork seals seem to start leaking between 6,000 and 50,000 miles depending

on the sort of riding that you do and how clean you keep the stanchions. 20,000

miles seems to be their usual life on UK roads. I have heard of the chrome

pitting after only 6,000 miles but this was on a machine that was severely

neglected. I hate cleaning the bike but I do wipe the tubes with WD40 after most

trips. No pitting yet. Some people say that gaiters keep the forks a good

condition, others that they trap dirt! The F650 forks are too small for real

dual-sport gaiters and too big for those for small commuter bikes. You'll find

that pattern K-series gaiters fit well and when secured with black cable ties

they look OK.

The job

In theory this is straightforward. In practice I failed to complete

it and I am told that it can be awkward for the technician. My advice is

do not start this job unless you have lots of experience with

Japanese forks and stuck seals. Therefore there's no more text!

Time and cost

My bike was off the road for nearly a month as I struggled. The 9 units of

BMW labour (to fit seals to loose forks) were well worth it. You might

choose to take the forks off and carry them to the dealer but I guess this may

be more inconvenient for you.

If you can correct or add to this information in any way please let me

know.

![]() If you get it

wrong it will be dangerous.

If you get it

wrong it will be dangerous.

![]()

![]() Before

beginning the job you must consider if you are likely to need to replace the

shims (i.e. adjust the clearance). This is a harder job, not yet described here,

that needs specialist parts and tools. Rumour has it that once the engine has

bedded in and the shims replaced at say 6000 miles then an averagely ridden

machine will not require replacement for many miles. Two of mine were reshimmed

(don't know which) by the dealer at 6000 miles. At 32000 miles they are still in

tolerance (a dealer checked it at 23000 miles).

Before

beginning the job you must consider if you are likely to need to replace the

shims (i.e. adjust the clearance). This is a harder job, not yet described here,

that needs specialist parts and tools. Rumour has it that once the engine has

bedded in and the shims replaced at say 6000 miles then an averagely ridden

machine will not require replacement for many miles. Two of mine were reshimmed

(don't know which) by the dealer at 6000 miles. At 32000 miles they are still in

tolerance (a dealer checked it at 23000 miles).